Types of Control Systems

You shall already go through my previous post (of different real-life examples) , so you can now surely expect what I will be talking about in this post.

The two most important classification of Control System is based upon ‘whether feedback is ‘present or absent’. Depending on this we can say whether any said system is ’Closed’ or ‘Open’ Control System. So let’s dig deep inside these two types of control systems first:

Open Loop System

In this type, there is no feedback present i.e there is no mechanism of correcting automatically the change in output by adjusting the input signal.

In other words, input and output are totally independent of each other(hence the output will remain constant for given input). A simple open-loop system can be shown as below:

Common examples:

1.Automatic Washing Machine

Once timer is fixed for a specific time interval, there is no relation between output(clean cloth) and input(adding washing powder,soap,water etc ) . The control action has nothing to do with the actual status of ‘clean’ cloth.

2.Fan

Once we switch on the Fan, it starts moving at a constant speed decided by its regulator position. If we want to change the speed, then we need to change regulator position (there is no means from which ,it can change speed by itself)

Closed Loop System

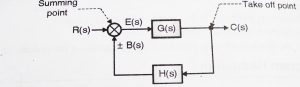

Once you understand the concept of Open-loop systems, Closed-loop systems are just the opposite(consists of feedback).In closed-loop systems, output and input are related and output is constantly monitored and adjusted to the required value by virtue of a feedback mechanism.

Thus in this kind of system, a correcting action will be taken by the feedback mechanism present. You may refer below figure for better clarity:

Common examples:

- Automatic dryer: Sensor will be present which will determine whether clothes have been properly dried or not and thus completing the feedback mechanism.

- Automatic Electric iron: In these type of irons, the temperature can be regulated based on temperature selection of cloth, the temperature will remain within the specified range (in this, a thermostat will be used in the feedback path) . When temperature exceeds specified range, heating will be stopped.

Advantages of Open Loop System:

1.Economical(cheap) to use

2.Maintenance will be easier

3.Simple in construction

4.No problem of stability(generally stable)

Disadvantages of Open Loop System

1.Recalibration of the system is required to maintain accuracy and quality

2.Internal disturbances can be a problem

3.Unreliable as accuracy depends upon recalibration

Advantages o Closed Loop System

- High bandwidth

- High accuracy(as error correction can be done)

- This system is less affected by noise

Disadvantages of Closed Loop System

- Very complicated and maintenance is expensive

- System may become unstable

- Overall gain reduced due to feedback

We can further classify any Control System based upon the linearity property as:

Linear system

These systems are strictly based on the principles of the Homogeneous and superposition principle.

ie; T[ax1(t)]+T[bx2(t)]=T[ax1(t)+bx2(t)] , where a and b are weighting factors,

Also if a = b, then we can also say that ka = kb (on multiplying by a constant ‘k’),

Also a1 + a2 = b1 + b2,

Basically, in a linear system, if you push thrice as hard, you get thrice the response, if you push 50x as hard, you get 50x the response(variation between input and output will follow linear characteristics)

In this system , an output can able to change its magnitude but however, its baseline form (initial form) never changes with respect to the input. Any sinusoidal input always give a sinusoidal signal in its output.

Stability of this system don’t depend upon the initial conditions. Thus response will be more predictable when we control it.

Non Linear system

They don’t follow the superposition principle and also the homogeneous theorem, at any time.

In a nonlinear system, there’s a more nonlinear relationship— maybe if you push 20x as hard, you get 200x the response.

In this , the output will change all its given parameter from the magnitude to phase and then to frequency. Input forms are nowhere realizable in this systems.

Adaptive Control System

Adaptive control is the control method that has been implemented by any controller that must adapt to a given restricted (controlled) system along with the parameters which normally change, or is initially very uncertain. It will automatically measure the dynamic characteristics(i.e the transfer function of state equation), and compares them with the required characteristics.

This type of control system can continuously measure its own performance index and modifies parameters such as optimal performance is achieved under any operating condition. For e.g. when any aircraft flies, its mass will slowly but gradually decrease as a consequence of the fuel consumption, a control parameter is hence required that adapts itself to such changing conditions.

This is similar to a normal (non-adaptive) controller, the parameters of which can be continuous and which consequently relies on the controller design and it doesn’t need any prior info about the bounds on these uncertain or the parameters that are time-varying in nature.

Feed Forward Systems

A feed forward controller detects the disturbance directly and takes an appropriate control action in order to eliminate its effect on the process output.

In this type of systems, output of one stage is sent to a later stage to improve the overall performance. In feed-forward system, corrective action is initiated without waiting for the effect of disturbances to show up in the output (unlike in feedback systems, where corrective action starts only after output has been effected)

An elected person who cast his vote as per his own conscience/thinking is working on the forward control system

One who takes into consideration the letters/phone calls/complaints/suggestions is working on the feedback principle.

Servo Mechanisms

These are basically the closed-loop systems, where feedback mechanism is used to control position, speed, velocity etc . Servo voltage stabilizers (in which position is controlled by means of servo motors ) is an example of Servo mechanism.

Characteristics of good control system:

Accuracy: Error detector should be used to increase accuracy. Basically this parameter should as high as possible. Feedback element can be used to sense any error arising.

Noise: This should be ideally negligible. A good control system should able to reduce noise or undesired inputs. Noise is nothing but an undesired input.

Stability: An efficient control system response must be stable for all the variations. The output should be zero in the absence of any input.

Speed: This should be high. Thus the output response will be very fast.

Sensitivity: A good control system should be insensitive to undesired input signals (noise) and should be sensitive only to the required input signals. It should sense the change and should correct the same.

Oscillation: This should be sustained or constant in nature.

Bandwidth: This should be large. The operating frequency range decides the bandwidth, thus good control system should have a large bandwidth.

Aric is a tech enthusiast , who love to write about the tech related products and ‘How To’ blogs . IT Engineer by profession , right now working in the Automation field in a Software product company . The other hobbies includes singing , trekking and writing blogs .